In the world of logistics, shipping, and supply chain management, safety is paramount. One crucial document that plays a pivotal role in ensuring safe handling, transportation, and storage of hazardous materials is the Material Safety Data Sheet (MSDS). Whether you're a logistics professional, a shipper, or a regulatory authority, understanding the MSDS and its importance in shipping is essential for compliance and safety.

What is a Material Safety Data Sheet (MSDS)?

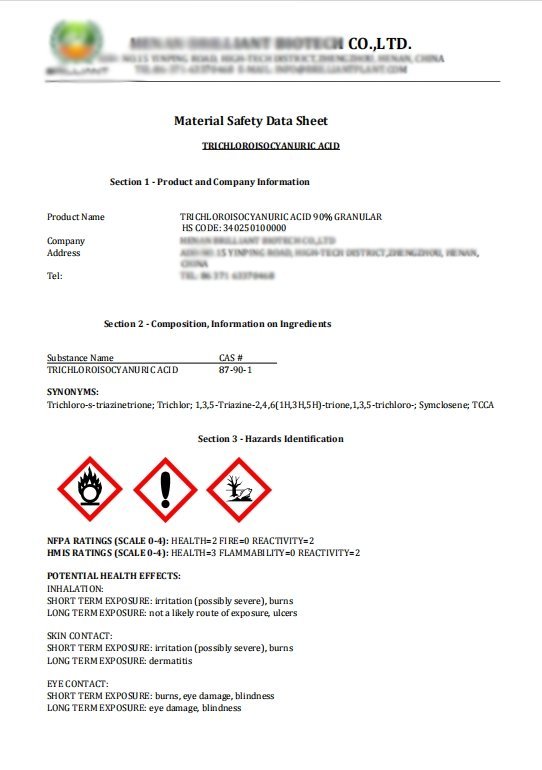

The Material Safety Data Sheet, commonly referred to as MSDS, is a standardized document that provides detailed information about a chemical substance or product. It is designed to communicate important safety, health, and environmental information about the material in question. The MSDS is typically prepared by the manufacturer or supplier of the product and is required by law in many countries for hazardous substances.

An MSDS includes critical details such as:

- Chemical composition: Ingredients and their concentrations.

- Physical and chemical properties: Information like boiling point, vapor pressure, and solubility.

- Hazard identification: Potential risks to health, safety, or the environment.

- First-aid measures: Steps to take in case of exposure or accidents.

- Handling and storage requirements: Guidelines for safe use and storage.

- Transportation guidelines: Classification and labeling requirements for shipping.

- Disposal considerations: Proper methods for disposing of the material.

- Regulatory information: Compliance with local and international laws.

The MSDS serves as a comprehensive guide for anyone who comes into contact with the material, ensuring they understand its properties and potential hazards.

Why is the MSDS Important in Shipping?

Shipping hazardous materials comes with inherent risks. Without proper documentation and precautions, these materials can endanger people, property, and the environment. The MSDS plays a critical role in mitigating these risks. Here are some key reasons why the MSDS is indispensable in shipping:

1. Compliance with Regulations

Shipping hazardous materials is heavily regulated at both national and international levels. Authorities like the International Maritime Organization (IMO), the International Air Transport Association (IATA), and local government agencies require proper documentation for hazardous goods. The MSDS provides essential information to classify materials under relevant regulations, such as the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals or the Dangerous Goods Code.

Failure to comply with these regulations can result in fines, shipment delays, or even accidents. The MSDS ensures that all parties involved are aware of the material's classification and handling requirements.

2. Safe Handling and Transport

The MSDS outlines specific precautions for handling hazardous materials during shipping. This includes instructions on packaging, labeling, loading, and unloading procedures. For example:

- Flammable liquids may require specialized containers to prevent leaks or spills.

- Corrosive substances might need protective barriers to avoid contact with other goods or surfaces.

- Certain chemicals may need temperature-controlled environments to remain stable.

By following the MSDS guidelines, shippers can minimize risks such as spills, fires, or chemical reactions during transit.

3. Emergency Response Preparedness

Accidents can happen despite best efforts to ensure safety. In such situations, having access to an MSDS is critical for emergency response teams. The document provides detailed first-aid measures, firefighting instructions, and spill containment procedures tailored to the specific material.

For example, if a chemical spill occurs during shipment, the MSDS will indicate whether water or a specific neutralizing agent should be used for cleanup. It also provides information on personal protective equipment (PPE) required for responders to safely handle the situation.

4. Environmental Protection

Many hazardous materials can pose significant risks to the environment if not handled properly. The MSDS includes guidelines for preventing environmental contamination during shipping and disposal. This ensures that shippers take necessary precautions to avoid leaks or spills that could harm ecosystems.

Additionally, some chemicals may have specific disposal requirements to prevent pollution. The MSDS ensures that these requirements are clearly communicated and followed.

5. Worker Safety

The safety of workers involved in the shipping process—such as warehouse staff, transport operators, and dockworkers—is a top priority. The MSDS provides them with crucial information about potential hazards associated with the material they are handling. It also outlines protective measures such as wearing gloves, goggles, or respirators to prevent exposure.

By adhering to the guidelines in the MSDS, companies can reduce workplace accidents and ensure compliance with occupational health and safety standards.

6. Facilitating International Trade

When shipping goods internationally, consistency in documentation is key. The MSDS serves as a universal reference that complies with global standards like GHS. This consistency helps streamline customs clearance processes and ensures that materials are handled appropriately across borders.

Best Practices for Using an MSDS in Shipping

To maximize the benefits of the MSDS in shipping operations, consider the following best practices:

- Ensure Accuracy: Always use the most up-to-date version of the MSDS provided by the manufacturer or supplier. Outdated information can lead to mishandling or non-compliance with regulations.

- Train Employees: Provide training for all employees involved in shipping hazardous materials so they can interpret and apply the information in an MSDS effectively.

- Maintain Accessibility: Keep copies of relevant MSDS documents readily available during all stages of shipping—loading, transit, unloading, and storage.

- Verify Compliance: Cross-check the MSDS against applicable shipping regulations to ensure full compliance with labeling, packaging, and transportation requirements.

- Communicate with Stakeholders: Share the MSDS with all parties involved in the supply chain, including carriers, warehouses, and end-users.

Conclusion

The Material Safety Data Sheet (MSDS) is more than just a document—it's a vital tool for ensuring safety, compliance, and environmental protection in shipping operations. By providing detailed information about hazardous materials, it empowers shippers to handle these substances responsibly while minimizing risks to people and the planet.

In an industry where even minor oversights can have serious consequences, incorporating the MSDS into your shipping processes is not just a regulatory requirement—it's a commitment to safety and professionalism. Whether you're transporting chemicals across town or across continents, let the MSDS be your guide to safe and efficient operations.