Freight class density is one of the most critical factors in determining shipping rates for Less Than Truckload (LTL) freight. It directly impacts the freight class, which is used to standardize shipments and determine costs based on the density and nature of the items being shipped. Understanding how freight class density works will help you avoid extra fees, prevent shipment delays, and ensure you’re getting the most accurate freight quote.

What is Freight Class Density?

Freight class density is calculated by dividing the weight of the shipment by its volume (in cubic feet). This determines the freight class, which impacts shipping costs and helps standardize the classification of goods. Freight class density is essential because it directly affects how much space your shipment takes up on a truck, influencing transportation costs.

Freight Class is Categorized by the National Motor Freight Classification (NMFC)

The NMFC system is used to assign freight classes to different types of goods based on several key factors that impact how the shipment is transported and handled. These factors help standardize the classification of freight across the industry, ensuring consistency and accuracy in determining freight rates and handling requirements. The primary factors that influence freight class include:

1. Density – How much space the item occupies in relation to its weight

Density is perhaps the most significant factor when determining a shipment’s freight class. It refers to the ratio of the item’s weight to the space it occupies, typically measured in pounds per cubic foot (PCF). Shipments with higher density (heavier items that take up less space) are assigned lower freight classes, making them cheaper to transport. In contrast, lighter items that take up more space but weigh less are assigned higher freight classes, leading to higher shipping costs.

For example:

- High-density items: Machinery or bricks, which are heavy but compact, typically fall into Class 50 or 55, resulting in lower costs because they take up minimal space relative to their weight.

- Low-density items: Items like pillows or insulation, which are lightweight but bulky, fall into Class 175 or higher, making them more expensive to ship due to the space they occupy in the truck.

The density factor ensures that carriers can optimize their space by charging more for items that reduce the available room in the truck.

2. Stowability – How easily the goods can be stowed on a truck

Stowability refers to how easily a shipment can be loaded, stored, and positioned in a truck or container with other freight. Items that are easy to stack, store, and fit into standard dimensions have better stowability and are assigned lower freight classes. Conversely, goods that are irregularly shaped, have odd dimensions, or require special accommodations (such as hazardous materials) will have a higher freight class because they take up more space or make it harder to maximize the load capacity of the truck.

Consider the following examples:

- Good stowability: Standard pallets or boxed goods that can be easily stacked and arranged without wasting space are assigned a lower freight class.

- Poor stowability: Items like oddly shaped machinery, large equipment, or goods requiring specific handling instructions (e.g., hazardous materials, liquids) may not fit neatly with other shipments, leading to higher freight classes due to the extra space they require.

Carriers prefer items with good stowability because they maximize the use of available space, reduce the need for special handling, and minimize wasted room.

3. Handling – How the goods can be handled during transit

Handling refers to how easy or difficult it is for the carrier to load, move, and unload the shipment. Goods that require minimal handling, such as boxed or crated items, are easier to transport and are typically assigned lower freight classes. However, items that are fragile, hazardous, or require special equipment (like forklifts or cranes) for loading and unloading will be assigned a higher freight class due to the additional time, care, and risk involved in handling.

For example:

- Easy to handle items: Standard-sized crates or boxes that can be moved with a pallet jack or forklift are easier to handle and have a lower freight class.

- Difficult to handle items: Fragile or hazardous materials, items requiring manual handling, or shipments with specific safety concerns (like chemicals) are more challenging to manage and are assigned a higher freight class.

Handling is a key factor because items that are harder to move often require more labor, time, and equipment, increasing the overall cost of shipping.

4. Liability – The risk of damage or theft associated with the goods

Liability refers to the potential risk of loss, damage, or theft of the goods during transit. Items that are considered fragile, high-value, or prone to theft carry higher liability for the carrier and are often assigned higher freight classes to account for this risk. Conversely, items that are durable, lower in value, or less likely to be damaged in transit are assigned lower freight classes, reducing the overall shipping cost.

Examples of liability considerations:

- Low-liability items: Durable goods like bricks, steel, or cement are less prone to damage and have lower freight classes because they do not require special protection or care.

- High-liability items: Expensive electronics, glass products, or perishable goods like food or pharmaceuticals have higher freight classes due to the increased risk of damage or theft. These items may require extra packaging, temperature controls, or special insurance, all of which increase shipping costs.

Carriers must account for liability when pricing shipments because higher-risk items can result in greater financial exposure if something goes wrong during transit.

How to Calculate Freight Class Density

To calculate freight class density, you need to measure both the dimensions and the weight of your shipment. The formula for calculating density is straightforward but essential for determining the correct class and avoiding overcharges.

Here’s a step-by-step guide:

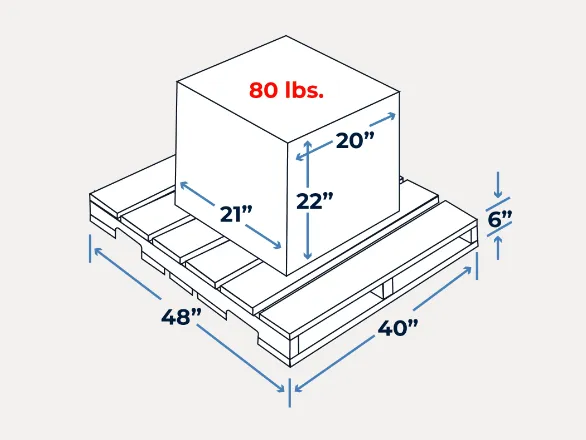

- Measure the dimensions of your shipment.

- Take the length, width, and height of your shipment in inches. Make sure to include any packaging or pallets in your measurements. For example, if your package is 48 inches long, 40 inches wide, and 36 inches high, these are your dimensions.

- Calculate the volume in cubic feet.

- Multiply the length, width, and height together to get the volume in cubic inches.

- 48 in×40 in×36 in=69,120 cubic inches

- Now divide this by 1,728 (the number of cubic inches in a cubic foot) to convert the volume to cubic feet.

- Weigh the shipment.

- Weigh the shipment in pounds, including packaging. For example, if your shipment weighs 800 pounds, this is the number you will use in the calculation.

- Calculate the freight density.

- Divide the weight by the volume to get the density.

- This gives you a freight density of 20 pounds per cubic foot.

- Determine the freight class.

- Based on the density, your shipment may fall under a specific freight class. In this case, a density of 20 pounds per cubic foot would likely fall under Freight Class 70.

Freight Class Density Table

Freight class is determined based on the density of the shipment, with classifications ranging from 50 to 500. Here’s a comprehensive table that outlines the different freight classes and their corresponding density ranges, along with common examples of goods in each class:

| Freight Class | Density (lbs per cubic foot) | Example of Goods |

|---|---|---|

| 50 | 50+ | Durable items (bricks, machinery) |

| 55 | 35-50 | Heavy raw materials (cement, hardwood) |

| 60 | 30-35 | Car parts, heavy accessories |

| 65 | 22.5-30 | Boxed books, bottled drinks |

| 70 | 15-22.5 | Furniture, crated goods |

| 85 | 12-15 | Clothing, small household goods |

| 100 | 8-12 | Food items, canned goods |

| 125 | 6-8 | Light electronics, packed foods |

| 150 | 4-6 | Fragile goods, light packaging materials |

| 175 | 3-4 | Bulky, lightweight items (pillows) |

| 200-500 | Less than 3 | Very light or dense goods (insulation) |

Understanding this table helps you interpret freight classes more accurately and can save you money by ensuring you assign the correct class to your shipment.

Why Freight Class Density Matters for Shipping Costs

Freight class density plays a significant role in calculating shipping costs. Lower-density shipments (those that take up more space but weigh less) typically fall under higher freight classes, which are more expensive to ship. For example, lightweight items like pillows may take up a lot of space relative to their weight, which could place them in Class 175 or higher, leading to increased shipping rates.

Conversely, heavier items with high density, such as machinery or bricks, occupy less space and are placed in lower, more cost-effective freight classes (Class 50 or 55). Properly calculating the density of your shipment ensures you’re using the correct class, preventing overcharges or disputes with carriers.

Common Mistakes to Avoid in Freight Class Calculations

Even small errors in calculating freight class density can result in higher shipping costs or rejected shipments. Here are some of the most common mistakes to avoid:

- Not including packaging in the measurements: When calculating dimensions, always include any packaging materials, crates, or pallets. Forgetting to include them will result in a lower density and potentially the wrong freight class.

- Assuming standard freight classes: Don’t assume that certain goods always fall into a specific class. Freight class is based on density, so even similar items can fall into different classes depending on their size and weight.

- Using estimated weights: Always use accurate weights when calculating freight density. Estimating or rounding the weight can lead to incorrect calculations, and ultimately, higher costs or shipment rejections.

- Ignoring shipment stowability and handling: While density is the primary factor in determining freight class, stowability (how easily items can be packed) and handling requirements (how the item will be moved) also play a role. Be sure to take these into account, especially when shipping delicate or oddly shaped items.

How to Use Freight Class Calculators

If you’re unsure about how to calculate freight class density manually, there are many online tools available to assist you. Freight class calculators allow you to input your shipment’s dimensions and weight, and they’ll automatically calculate the density and recommend a freight class. These tools are helpful for quick estimations and ensuring you’re using the right class when booking shipments.

Sonuç

Accurately calculating freight class density is key to optimizing shipping costs and avoiding unnecessary fees. By following the steps to measure your shipment’s dimensions and weight, you can calculate the correct density and assign the appropriate freight class. Whether you’re shipping durable machinery or lightweight goods, understanding how density impacts freight class ensures you’re getting the most accurate shipping rates. Make use of freight class calculators or consult professionals when necessary, and avoid common mistakes to streamline the shipping process.